The process of how leather is made hasn’t changed much over the past several thousand years. Finishing techniques and technology have evolved over the years, but the basic process has more or less remained the same.

The entire process of making leather and preparing it for manufacturing is lengthy and complicated, and is performed by skilled artisans, known as tanners. It takes an average of 10 working days to turn hides into finished leather.

The hide of almost any animal can be used to make leather, including sheep, goats, cows, pigs, crocodiles, and even snakes. Cow hides tend to be the most commonly used, due to their larger size and abundance (by-products of the meat and dairy industries) that would otherwise be destroyed.

During this 23-step tutorial, we will show you how leather is made from a salted hide to a high quality piece of leather:

Here’s the process of making LEATHER AND PREPARING IT FOR MANUFACTURING HANDBAGS, FOOTWEAR, and GARMENTS:

1. curing the hides

Hides, the term used for animal skins used in leather production, must be preserved, or cured, in order to prevent deterioration. Preservation methods often involve salting, chilling, freezing, or the use of chemicals.

2. SOAKING THE HIDES

After the hide is cured, it is left soaking in water for several hours, or even days, i order to rehydrate the hide and remove any excess salt, chemicals, or dirt from curing and transportation.

3. PAINTING THE HIDES

Don’t be confused by the term – in leather making, painting refers to removing the wool from sheep skins, using sulphides.

4. LIMING THE HIDES

The primary function of this step is removing any unwanted hair from the hide by introducing alkali. After the hair has been removed, we now have raw animal skin, also referred to as a pelt.

5. FLESHING THE PELTS

As the name suggests, fleshing is the process of passing the pelt through a machine which removes the tissue from the flesh (back) side. In some cases, a pelt will also be split into layers at this stage.

6. DE-LIMING THE PELTS

During this step, the alkali in the pelt is gradually neutralized. This must be done gradually, since rapid change in acidity can cause distortion of the tissue.

7. BATING THE PELTS

Enzymes are now applied to the pelt, which helps to relax and flatten the pelt.

8. PICKLING THE PELTS

During this step, the salt solutions or weak acids are applied to the pelt. A mildly acidic PH is required for tanning. A strong solution may be applied to preserve the pelts if the tanning won’t occur for several months.

9. DE-GREASING THE PELTS

Prior to tanning, excess grease is removed from the pelt with a mild solvent, or water.

10. TANNING THE PELTS

Tanning chemically changes the structure of collagen in a pelt, so that it is protected against moisture, chemicals, and microorganisms. In simple terms, proteins in a pelt are converted into a stable material. This can be done several ways including:

Minerals: A mineral, such as salts of chromium (chrome tanned), is the most common leather tanning material. The chrome turns the hides into a bluish color, in which the unfinished hides re referred to as wet-blue.

- Oils: When a pelt is tanned with oil, the result is a much softer leather for wearable products.

- Vegetables: Plant extracts may be used to produce thick, firm, leather (typically brown or natural colors), ideal for belts, shoes, bags, and cases.

11. SPLITTING THE LEATHER

When splitting the leather, the leather is split horizontally into layers (depending on the thickness, it can be split up to 9 times!), leaving us with a top layer (or top grain leather), and back layers (split leather).

12. SHAVING THE LEATHER

Using the top grain piece, another machine is used to shave the back (non-grain) side, to the desired thickness. Scraps from shaving can be used to make bonded leather and recycled leather.

13. Neutralizing THE LEATHER

14. DYEING THE LEATHER

At this point, pigmentation is applied to achieve the desire color. The most common method of dying is in large rotating drums, which is called drum-dyed.

15. FATLIQUORING THE LEATHER

16. Samming THE LEATHER

Moisture must be removed from the leather (by almost 50%) before ready for final production. This is done by machine.

17. STRETCHING THE LEATHER

Now, the leather is stretched and smoothed out. During this stage, any remaining moisture in the leather is further reduced.

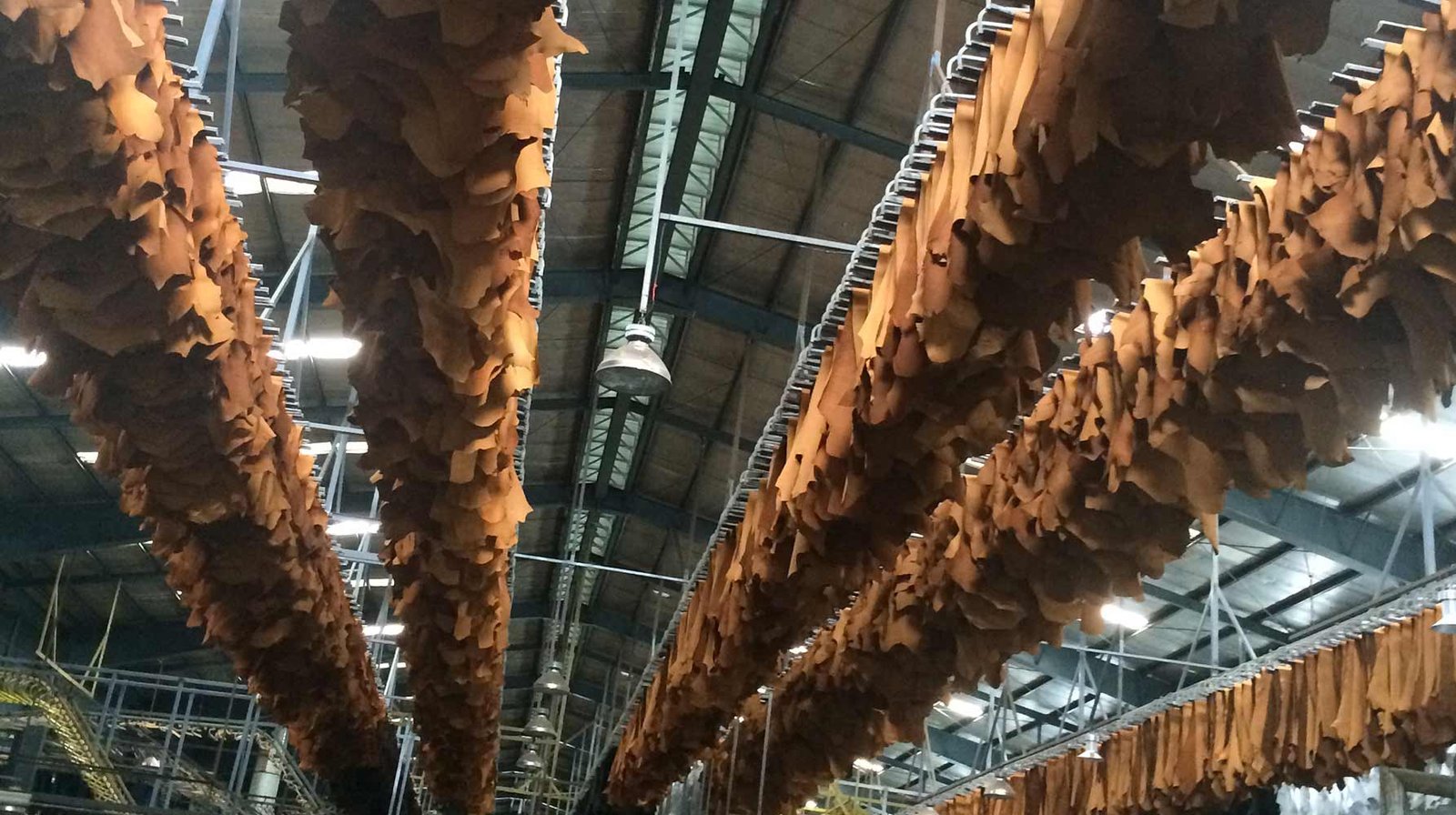

18. FINAL DRYING OF THE LEATHER

The leather is hung to dry, generally until the water content is about 20% or less.

19. STAKING AND DRY DRUMMING THE LEATHER

A staking machine is used In order to ensure that the leather is flexible and soft. Once staked, the leather is then placed inside a rotating drum (without any dye) for additional tumbling.

20. BUFFING + BRUSHING OF THE LEATHER

The back (flesh side) of the leather is now completely removed through buffing, to produce a softer feel, clean up (in the event of exposing the back side for fringe, an unlined handbag, etc). After buffing, a thorough brushing occurs to remove any dust produced during buffing.21. LEATHER FINISHING

22. Grading the leather

Before selling the leather to a manufacturer, the tannery must grade the thickness, uniformity, hand feel, color, softness, and texture. Naturally occurring defects, including scratches, bite marks, etc, are also noted during final grading of the leather. At this point, the leather may also be tested for qualities such as colorfastness, tensile strength and tear load, safety and chemical properties, and resistance to cracking under various environmental conditions. Samples of the leather may also need to be sent to a third-party testing facility if required by the manufacturer or country of import.

23. final measurement

Our Designers and Technicians have extensive training in leather making and its use in design and manufacturing.If you would like more information on sourcing or developing custom leather for your collection, contact us for a free consultation.

Not into using leather for your product but need a leather-look?

Read more about Vegan leathers and sustainable options here.

Thread and Butter Design Agency is a full service fashion design agency with global manufacturing partners for handbags, footwear, and apparel.

About Us

Thread & Butter takes inspiration from trends around the world and delivers thoughtful, creative design solutions with a whimsical and eclectic attitude. Our work is exciting, demanding, outstandingly creative, and strikes a delicate balance of being of the moment, yet timeless. We are the thread that connects your brand to the world, seamlessly.

See our work

How Leather is Made

Ever wonder how leather is made? Here's the 23-step process of making leather and preparing it for manufacturing handbags, footwear,…

Read more

A Peek at Chic Upcycled Accessory Brand Tega Akinola

Tega Akinola, a young 22 year old designer from the UK, is turning thrifted socks and sweaters into chic upcycled…

Read more

How Hardware is Made for a Handbag

When designing a handbag collection, you may want to create your own custom branded hardware to make your product unique…

Read more

2022 UX and UI Design Trends

Consumer behaviors, attitudes, and buying habits have all been changed by COVID-19. The overwhelming shift towards eCommerce over in-store experiences,…

Read more

NIKE acquires NFT company RTFKT – Digital Fashion Trends

The massive deal between NIKE and RTFKT paves the way for fashion and a magnificent breakthrough into the world of…

Read more

How to Launch a Successful Fashion Brand

You are passionate about fashion. You want to launch a fashion brand or clothing line, but you don't know how…

Read more